Copper brazing alloy refers to the alloy material used for brazing on copper substrate. These alloys usually have a low melting point and can melt and fill the joint gap without melting the copper substrate, forming a good metallurgical bond with the copper substrate.

Cu、P.

① Easy to install and disassemble: Good fluidity during welding, can flow into small spaces.

② Moderate melting point: Good fluidity during welding, perfect performance under gas flame, induction and furnace brazing methods, outstanding oxidation resistance at high temperature, excellent corrosion resistance and fatigue resistance after welding, suitable for high temperature and high pressure environment.

③ Good joint strength and conductivity: It can quickly transfer heat and achieve precise temperature control, ensuring stable and efficient welding process, perfect for MAPP, MAP, propane and oxygen acetylene gas welding gun settings.

④ No need to use brazing flux: When brazing copper with copper-phosphorus brazing alloy, the phosphorus in the brazing alloy plays the role of brazing flux.

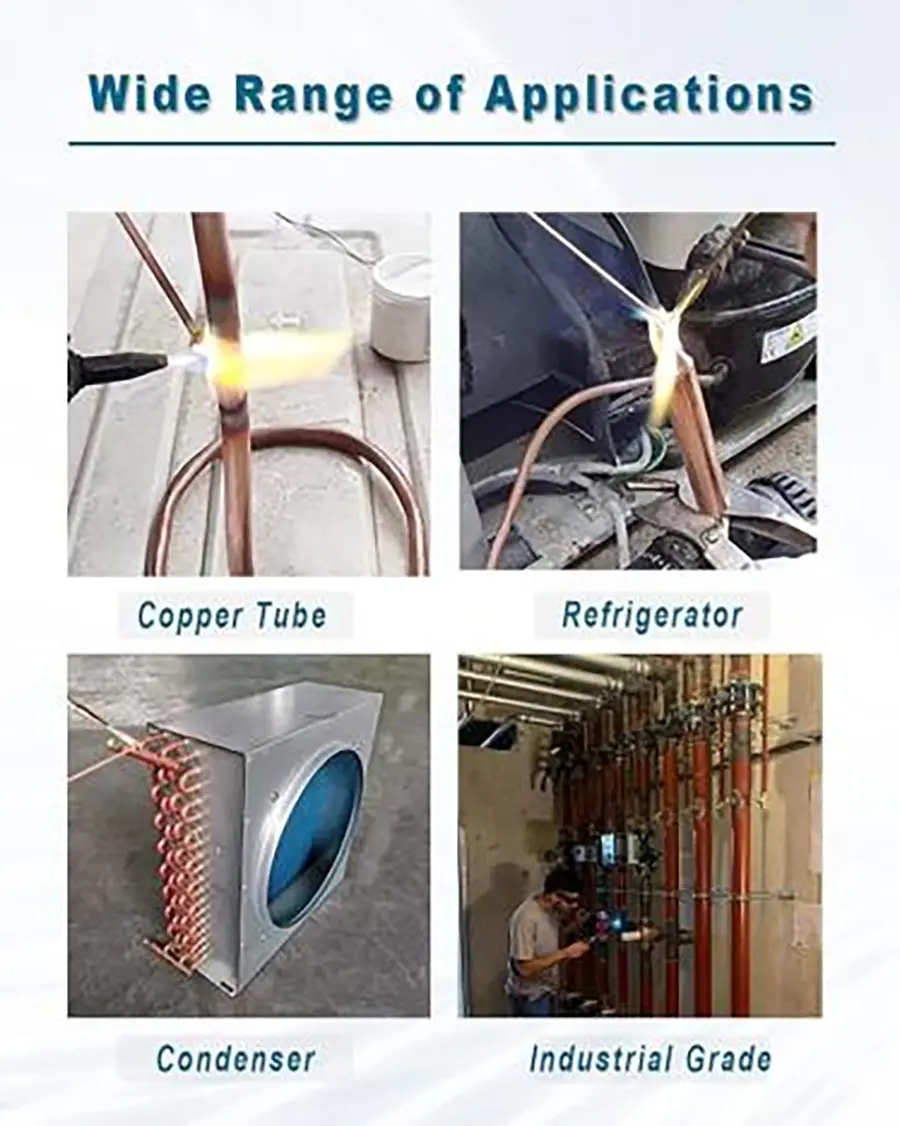

A popular and economical solution for HVAC, plumbing and mechanical repairs, used for brazing of copper and copper alloys in motor, instrumentation and refrigeration industries, very suitable for gas welding, contact welding and some furnace welding, suitable for brazing copper to copper, brass and bronze joints in air conditioners, freezers, evaporators, heat exchangers, water heaters, etc.

| Code | Related Standard | Chemical Composition | Melting Temperature | Code | Related Standard | ||

| P% | Cu% | Solidus℃ | Liquidus℃ | ||||

| JCuP-1 | CWA:BCu92P | 7.5-8.5 | REM | 710 | 780 | JCuP-1 | CWA:BCu92P |

| JCuP-2 | CWA:BCu93P AWS:BCuP-2 | 6.5-7.5 | REM | 710 | 800 | JCuP-2 | CWA:BCu93P AWS:BCuP-2 |

| JCuP-3 | 6.1-6.8 | REM | 710 | 820 | JCuP-3 | ||

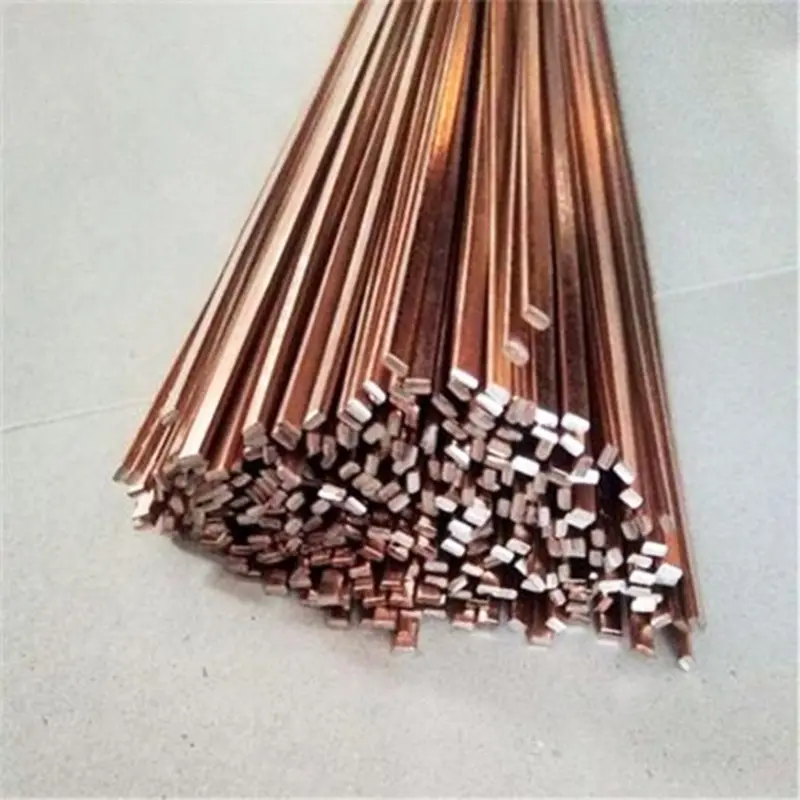

| BCuP-2 Brazing Rods Size | |

| Flat | 1.3×3.2x457mm |

| 1.3×3.2x500mm | |

| Square | 3.2×3.2x500mm |

| Round | 1.5x500mm |

| 2.0x500mm | |

| 3.0x500mm | |

Note: All sizes are Taojun standard, other sizes can be produced according to customer requirements.

Standard export seaworthy packing: with polyethylene film including drier, put them in carton; 5.67kgs/pvc bag, 11.34kgs/carton box;or 5kgs/pvc bag, 10kgs/carton box;