This filter adopts a customised extrusion process developed by a team of professional engineers, which makes the product’s inlet and outlet ends more compact and sturdy in structure, and significantly improves durability. By flexibly adjusting the parameters of the mould, it can be shaped in one go to accurately match the diversified needs of customers. During the production process, each piece of equipment is controlled by specialised personnel in full-process quality control to ensure that product quality meets the highest standards. The highly efficient production line is capable of producing 5,000 filters a day, ensuring an adequate supply of products. This filter is not only compact in design and easy to install, but also the molecular sieve used is suitable for R134A, R600A, R410A, which is the first choice of foreign manufacturers of refrigerators, freezers, water dispensers, air conditioners and refrigeration equipment.

Extruded copper filter stands out among many filter products with its excellent performance and unique advantages. Firstly, copper is made of thicker material with natural antibacterial properties, effectively inhibiting the growth of bacteria and microorganisms and ensuring pure and safe water quality. Secondly, the high filtration precision of copper filter can effectively remove impurities, sediment, rust and other harmful substances in the water, providing clearer and healthier drinking water. In addition, the copper material is corrosion-resistant and has a long service life, which can work stably in various environments and reduce the frequency of maintenance and replacement.

Molecular sieve desiccant pre-adsorption rate, static water adsorption rate, shape and particle size, bulk density Crush resistance, adsorption rate, abrasion rate, molecular sieve filling amount, dust amount, impurity diameter, filter cloth and mesh ring frame bonding strength, mesh ring frame bonding strength, filter mesh bonding strength, compression resistance and airtightness, internal cleanliness, internal and external surface quality of the tube is higher than the national standard implementation.

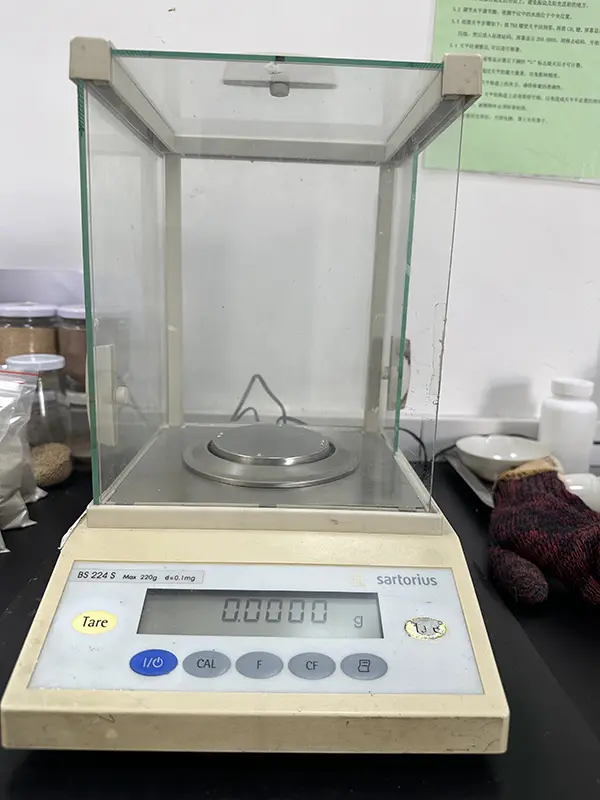

The following are laboratory research and development equipment for molecular sieve desiccant.

1. Structure and materials

Shell: high-purity copper tube (rust-proof, high-pressure resistant)

Inner core: 3A molecular sieve (water absorption rate ≥ 20%) + activated carbon layer

Sealing process: argon arc welding, to ensure no leakage

2. Core advantages

Extend the life of the equipment: reduce the corrosion of water and acid on the compressor

Rapid cooling: reduce system resistance and improve refrigerant circulation efficiency.

Wide range of uses: domestic refrigerators, commercial cold storage, automotive air conditioning can be used.

3. Application Scenario

Maintenance and replacement of refrigerator/freezer

Maintenance and upgrading of air-conditioning system

Maintenance of industrial refrigeration equipment

| Model | Molecular sieveS +5%,-0% | Body Diameter | Total length ±2 | Inlet (hner Dia) +0.1 | Outlet(Ihner Dia) +0.1 |

| TJK-15 | 15 | 19 | 115 | 6.5mm | 2.5mm |

| TJK-15 | 15 | 19 | 115 | 5mm | 2.5mm |

| TJK-20 | 20 | 19 | 140 | 6.5mm | 25mm |

| TJK-30 | 30 | 24 | 140 | 6.5mm | 2.5mm |

| TJK-40 | 40 | 24 | 170 | 6.5mm | 2.5mm |

Note:all size are TAOJUN standard,other size can be made on request.

Packaging is usually paper drums or iron pass packaging 700pcs/barrel